Yazi kulo lonke eli nqaku zonke iinkcukacha malunga ulawulo lwamanani, inkcazo ebalulekileyo yeenkqubo zayo kunye nokusetyenziswa abanokukunika, kweli nqaku uza kwazi ngendlela ethile nelula yonke inkqubo ebandakanya oku.

Ulawulo lwamanani

Yindlela ezenzekelayo yoomatshini abalawulwa yinkqubo yemiyalelo kwindawo yokugcina.

Umatshini wokuqala wolawulo lwedijithali wenziwa yinjineli uJohn T. Parsons ngeminyaka yoo-1940 noo-1950.Wawusekelwe koomatshini abakhoyo nabaneemotor eziguqulweyo, inani lazo lalinxulumene ngesandla nemiyalelo enikwe kwimakroskopu yekhadi lokugqibela.

Ezi ndlela zokuqala ze-servo zakhula ngokukhawuleza ngoncedo lwezixhobo ze-analog kunye nezidijithali. Ukungaxabisi kunye nokusetyenziswa kancinci kweprosesa basebenzise kakhulu itekhnoloji yedijithali kuzo zonke iintlobo zezixhobo, kukhokelela kwigama lolawulo lokugqibela lwedijithali, ulawulo lwekhompyuter yedijithali, ukuthelekisa noomatshini abangenazo iikhompyuter.

Le ndlela ilutshintshe ishishini ke ukuba olu hlobo lwentetho lusetyenziselwa ukubhekisa kolu hlobo lwezifundo ezazingenazo iikhompyuter, ke enkosi kwii-microprocessors ezingabizi kakhulu kunye nenkqubo eyenziwe lula yomatshini.

Imigaqo yokusebenza

Inkqubo isekwe ekubekeni iliso ekushenxisweni komatshini ngokunxulumene nentonga yokulungelelanisa izixhobo kusetyenziswa inkqubo yekhompyuter eyenziwe yikhompyuter. Kwilitha, ukufuduswa kwento eyenziweyo kufuneka kulawulwe kwii-axes ezimbini zokulungelelanisa: i-axis ye-X isetyenziselwa ukufuduswa kwexesha elide kwenqwelomoya kunye ne-axis ye-Z isetyenziselwa ukufuduselwa ecaleni kwinqaba.

Kumatshini wokugaya, ukufuduswa nkqo okuhambelana ne-Y axis nako kuyalawulwa.Ngalesi sizathu, zombini i-lathe kunye ne-turret displacement mechanism zifakwe kwi-servo motors, kwaye kwimeko ye-lathe ngumatshini wethebhulethi, umatshini wokugaya kuxhomekeke kubuchule bomatshini, ayinakulinganiselwa kwizembe ezintathu.

Izicelo

Ingasetyenziselwa ukumodelisha isinyithi, indawo yokudibanisa, ukuchwela, iiplastiki, iisekethi eziprintiweyo zombane, phakathi kwabanye. Ukusetyenziswa kwenkqubo ye-CNC kumatshini sisixhobo esonyusa ukusebenza kwaye kwangaxeshanye kuvumela ukwenza imisebenzi ekunzima ukuyigqiba ngezixhobo zomatshini eziqhelekileyo, ezinjengokufezekisa umphezulu wokungqukuva ngelixa ugcina inqanaba eliphezulu lokuchaneka komlinganiso.

Okokugqibela, ukusetyenziswa kwe Ulawulo lweenombolo zekhompyuter Inefuthe eliluncedo kwiindleko zemveliso ngokunciphisa iindleko zokuvelisa zoomatshini abaninzi kunye nokuphucula umgangatho.

Ukusetyenziswa kwe-CNC kunokothusa olwenziweyo kwiindleko zemveliso ngokunciphisa iindleko zokwakha zoomatshini abaninzi, ukugcina okanye ukuphucula umgangatho wazo.

Inkqubo kulawulo lwamanani

Olu hlobo lwenkqubo lusebenzisa iindlela ezimbini:

Inkqubo yesandla

Kule projekthi, icandelo libhalwa ngokukodwa ngokuqiqa kunye nokubala okwenziwa ngumqhubi kuphela, iprojekthi yokwenza izinto ibandakanya yonke idatha efunekayo kulungiso lwenxalenye.

Ukusukela ukuba umenzi ngamnye asebenzise eyakhe inkqubo ye-NC, ukuqala kwenkqubo ye-NC kubonakala ngokuphuhla okungagungqiyo kwikhowudi yenkqubo. Emva koko, ukuba iindidi zeenkqubo ziyafana, isidingo sokubeka emgangathweni ikhowudi yenkqubo yimeko ebalulekileyo yenkqubo enye eza kusetyenziswa koomatshini abohlukeneyo.

Inkqubo ezenzekelayo

Xa sithetha ngenkqubo sithetha ngento eyenziwa yikhompyuter xa idatha ibonelelwa ngulowo wenza inkqubo yesahlulo, ivela kulwimi lotshintshiselwano olubizwa ngokuba yi-APT, eya kuthi ke iguqulelwe kulwimi olufanelekileyo kulwimi ngalunye ngumqhubekekisi, ulwimi lomatshini.

Ukuchaneka

I-axis yaba matshini ihlala iqhutywa yinqwelo yokuhamba eyahlula i-360 degrees ujikelezo lube ngamanyathelo angama-200 ala manyathelo. Ke ngoko, ukuchaneka kwe-axis kuya kunikwa sisandi se-axis ephambili. Kule meko, inani lamanyathelo li-200, indawo ejikelezayo yesixhobo, umzekelo: ukuba i-X-axis spindle ene-1mm yahlulwe yangamanyathelo angama-200 emoto, isixhobo somatshini sinokubonelela ngokuchaneka kwe-0,005 mm kule axis.

Ngaphambi nasemva kolawulo lwamanani (CNC)

Ukusukela ekuqaleni kwenkulungwane yama-60, ukwanda kwemizi mveliso kunye nokusetyenziswa kakhulu koomatshini abasebenza ngemoto kuye kwafuna ukusoloko kukhangelwa iinkqubo ezifanelekileyo. Kude kube malunga neminyaka engama-65-XNUMX eyadlulayo, umsebenzi onzima ofunekayo kwimisebenzi yezamashishini awufunanga kuphela iqela elikhulu labasebenzi, kodwa uchaphazele nomgangatho, ukuchaneka nokuphindeka, ukwanda kweendleko kunye nokunciphisa imveliso.

Singayibona kangakanani ngomzekelo olula. Umzekelo, abantu abaninzi abasebenza kwivenkile yomatshini baqhelene nenye yezona zinto zilula zokuzenza, nkqu nokubhola imingxunya kwishiti yentsimbi kunye ne-drill yesandla.

Ukwenza oku, umqhubi kufuneka enze imisebenzi emininzi: beka ipleyiti kumgangatho wokugrumba, ubeke isuntswana kwi-chuck kwaye uyilungise kwindawo yokuluka, khetha isantya ngokutshintsha i-pulley, yenza i-spindle isebenze i-lever okanye i-roller roller iphepha likhokela umngxunya kwiphepha eliza kwenziwa.

Ngoku khawufane ucinge ngokusebenziseka kwenkqubo enjalo kwindawo yemizi-mveliso, apho amakhulu emingxunya kufuneka enziwe kumakhulu amaphepha ngexesha elifutshane elinokubakho ngexabiso eliphantsi kunye nomgangatho ophezulu wemveliso.

Yile ndlela ke eyathi yaziswa ngayo le migaqo yokulawulwa kwamanani (i-NC) koomatshini bokugaya baseMelika ngeminyaka yoo-1950.

Kwasekuqaleni kweminyaka yama-1960, iityhubhu zokucoca izinto zatshintshwa zatshintshwa ngabaguquleli, de kwafika iikhompyutha ngoo-1970 zabeka isiseko esicacileyo sento esiyibiza ngokuba yitekhnoloji ye-vacuum. ulawulo lwamanani ngekhompyutha (CNC).

Ezi chips zitshintshe indawo yonke kulawulo lwamanani kwaye ziye zaqonda ukudityaniswa kwemisebenzi, njengesincedisi kwinkqubo ephambili, ukubonakaliswa kwemizobo yezixhobo, kunye nemijikelezo yenethiwekhi.

Ezi chips ziye zanomdla opheleleyo kule ndima yokubeka esweni kwaye baqaphela ukudityaniswa kwemisebenzi, enje ngezixhobo eziphambili zenkqubo, ukubonakaliswa kwemizobo yendlela, ii-subroutines kunye nemijikelezo enkonkxiweyo, unxibelelwano kunye neenethiwekhi.

Ngexesha le-90s, ulwazi lwe Ulawulo lweenombolo zekhompyuter.

Ekuqaleni kweminyaka engama-90, ulwazi oluvulekileyo lwe-CNC lwaziswa, oluyivumela ukuba yenziwe ngokwezifiso kwaye idityaniswe nolwazi lomntu, ukucwangciswa komzobo onxibelelanayo, unxibelelwano lwedijithali kunye nedrive kunye nezinye izibonelelo ezininzi ezisinike izisombululo ezibalulekileyo koomatshini bokubeka esweni.

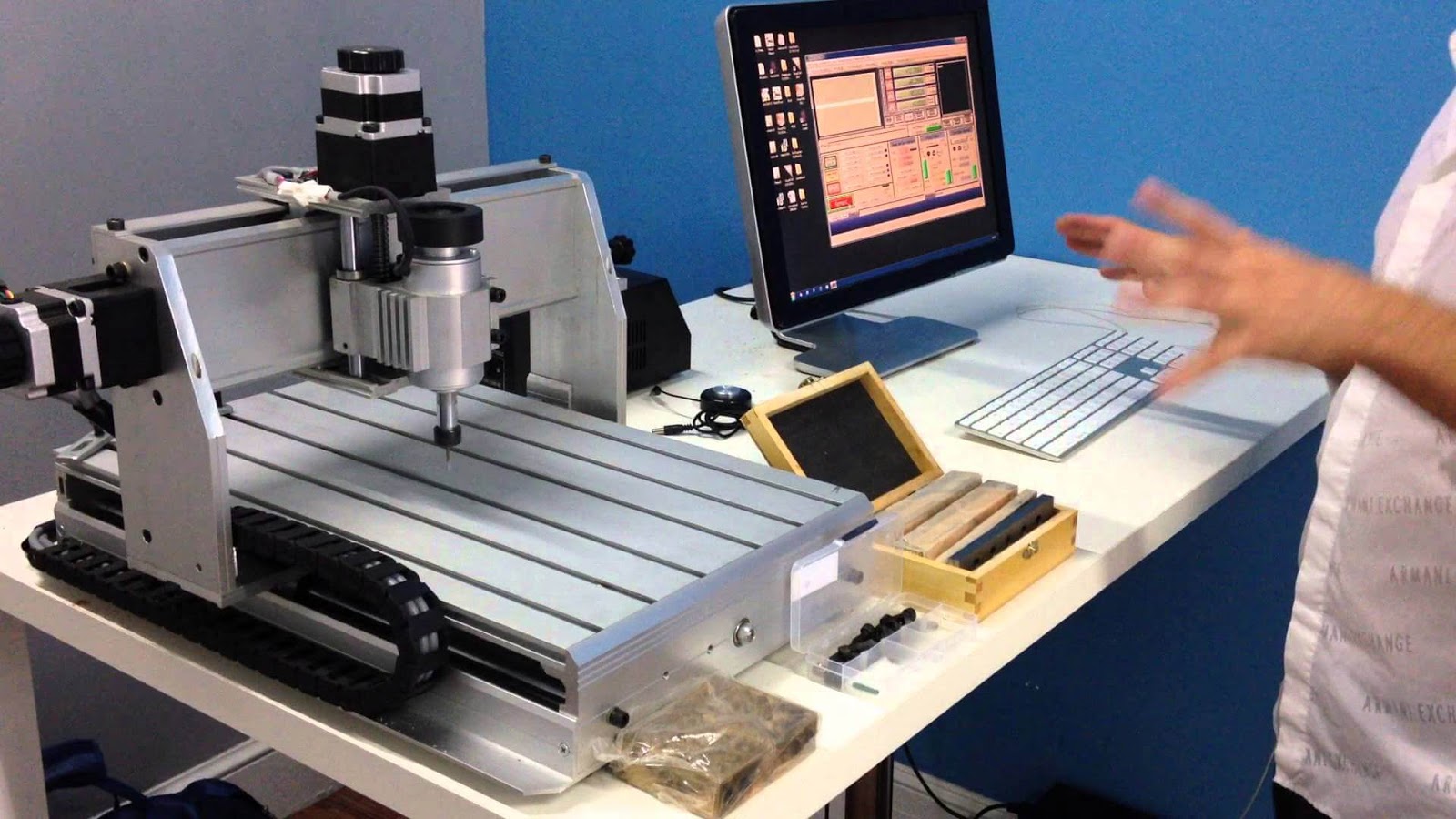

Usebenza njani umatshini we-CNC?

Oku kulawula umatshini ngokusisiseko kwaye ufumana iiodolo ngohlobo lweekhowudi kwiikhompyuter kwaye uzitshintshe zibe ziimpawu zombane ngesoftware yakhe ukuqala injini. Nje ukuba baqale inkqubo yokuhambisa, ii-axes zoomatshini be-CNC ziyimfuneko ukuvelisa iintshukumo ezifunekayo kwinkqubo yokuvelisa.

Ukuba siyaqhubeka nokusebenzisa uqheliso kwimizi-mveliso njengomzekelo, ezi mazembe ziya kubeka isixhobo emngxunyeni oza kwenziwa ngomatshini (iiazisi ezimbini) kwaye ziya kwenza umsebenzi (i-axis yesithathu), ii-axes zithiywa ngoonobumba, awona magama aqhelekileyo kwizembe zomgama zi-X, Y kunye ne-Z, ngelixa amagama aqhelekileyo kwizembe ezijikelezayo zi-A, B, no-C, iinkqubo ezimbini ezinokusetyenziselwa ulawulo lwentshukumo. Ezi nkqubo zimbini zinokusebenza ngokuzimeleyo okanye ngokudibeneyo.

Ixabiso elingapheliyo, apho ulungelelwaniso lwendawo lubhekisa ekuqaleni kwezi zinto, sebenzisa izinto eziguquguqukayo X (ixabiso elilinganisiweyo lobubanzi bokugqibela) kunye no-Z (kulinganiswa kwicala elilinganayo ne-axis yokujikeleza kwesikrufu).

Ixabiso elonyukayo, apho ulungelelwaniso lwendawo leyo lubhekisa kumanqaku akhoyo ngoku, sebenzisa uguquguqukayo u-U (umgama weradial) kunye no-W (kulinganiswa kwicala elingqamene ne-axis yokujikeleza kwe-axis ephambili).

Izinto ezinokucwangciswa

Ukuba kukho ukulawulwa kokuhamba kuphela, oomatshini be-CNC abayi kuba namsebenzi, phantse bonke oomatshini banokucwangciswa ngezinye iindlela, yiyo loo nto kufuneka sithathele ingqalelo ukuba umatshini unxulumene ngqo nezixhobo ezifanelekileyo, ngoko ke nayiphi na imisebenzi efunekayo. iqulunqwe kwisixhobo somatshini we-CNC. Ke ngoko, umzekelo, iziko lokuchwetheza liya kuba ubuncinci kule misebenzi ilungiselelwe:

Amaziko oomatshini kunye nesitshintshi sesixhobo esizenzekelayo anokulungiselela izixhobo ezininzi kwibhokisi ephathekayo. Ukuba kukho imfuneko, eyona nto iyimfuneko inokufakwa ngokukhawuleza kwi-spindle ukuze ihambelane nokusebenza.

Isantya sokujija kunye nokusebenza: Unokunika nje iinkcukacha ngesantya sokujija (nge-rpm), isilinganisi esingaphezulu asikwazi ukuqengqeleka ngokujikeleza kwewotshi okanye ngokuchaseneyo newashi, kodwa sime.

Ifriji: Oku kuyimfuneko kwimisebenzi emininzi efuna ifriji yokuthambisa kunye nokupholisa isixhobo, inokusebenza kwaye ingasebenzi ngexesha lomsebenzi.

Inkqubo ye-CNC

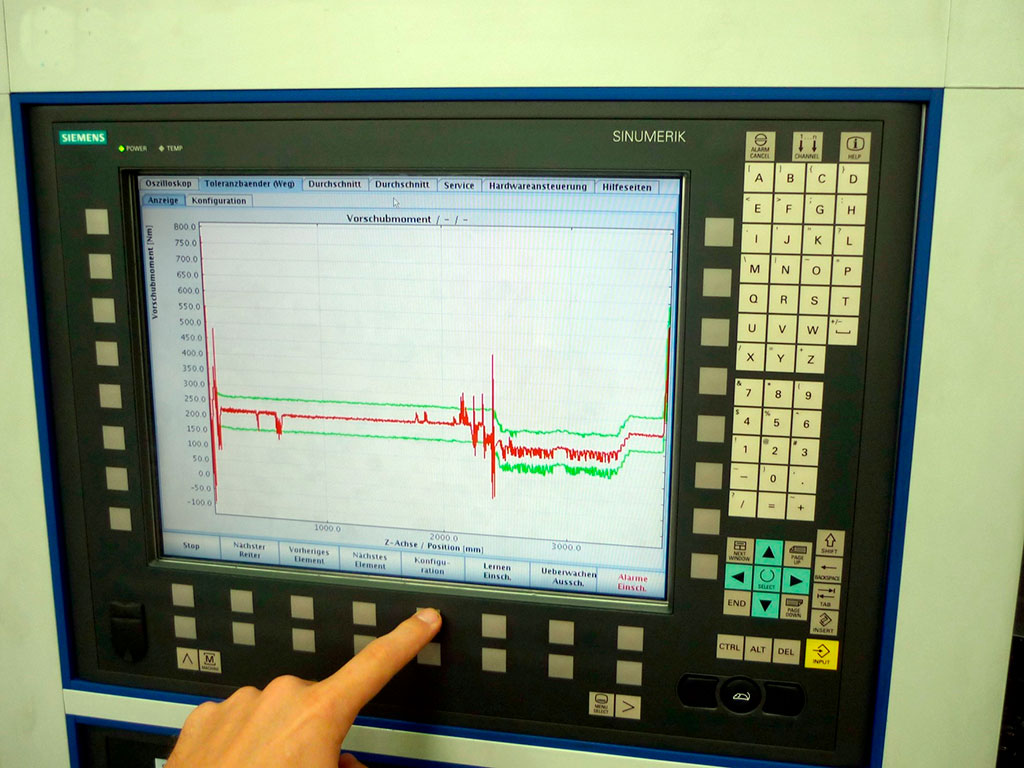

Le nkqubo isekwe kuluhlu lokulandelelana apho inemiyalelo yokuphumeza khona, ezi zikhombisi zibizwa ngokuba ziinkqubo ze-cnc, ekufuneka iqulathe lonke ulwazi olunyanzelekileyo kumatshini.

Iinkqubo ze-CNC zibhalwe ngeelwimi ezisezantsi ezibizwa ngokuba yi-G kunye no-M, zibekwe emgangathweni yi-ISO 6983 (uMbutho waMazwe ngaMazwe wokuBekwa emgangathweni) kunye ne-EIA (i-Electronic Industries Alliance) i-RS 274, kwaye yenziwe ngemiyalelo ngokubanzi (G ikhowudi) kunye nezinye (Ikhowudi M).

Inkqubo ibonelela ngefomathi yesivakalisi eyenziwe ngeebhloko, ukuqala ngonobumba N, njengoko kubonisiwe kumfanekiso olandelayo, apho isenzo ngasinye okanye isenzo senziwa ngokulandelelana, ibhloko nganye inenombolo kwaye ngokubanzi iqulethe umyalelo.

Kukho iikhowudi ezichaza imisebenzi yokuhamba kwezixhobo ezichaphazelekayo (umzekelo, ukuqhubela phambili ngokukhawuleza, ukuqhubela phambili, ikhefu, umjikelo), ngelixa ezinye iikhowudi zichaza eminye imisebenzi eyimfuneko ekwenzeni izinto ezithile, kodwa azihambelani nentshukumo izixhobo (umzekelo, ukuqala kokuluka KANYE nokuyeka, ukutshintsha kwesixhobo, ukupholisa, ukumisa kwenkqubo).

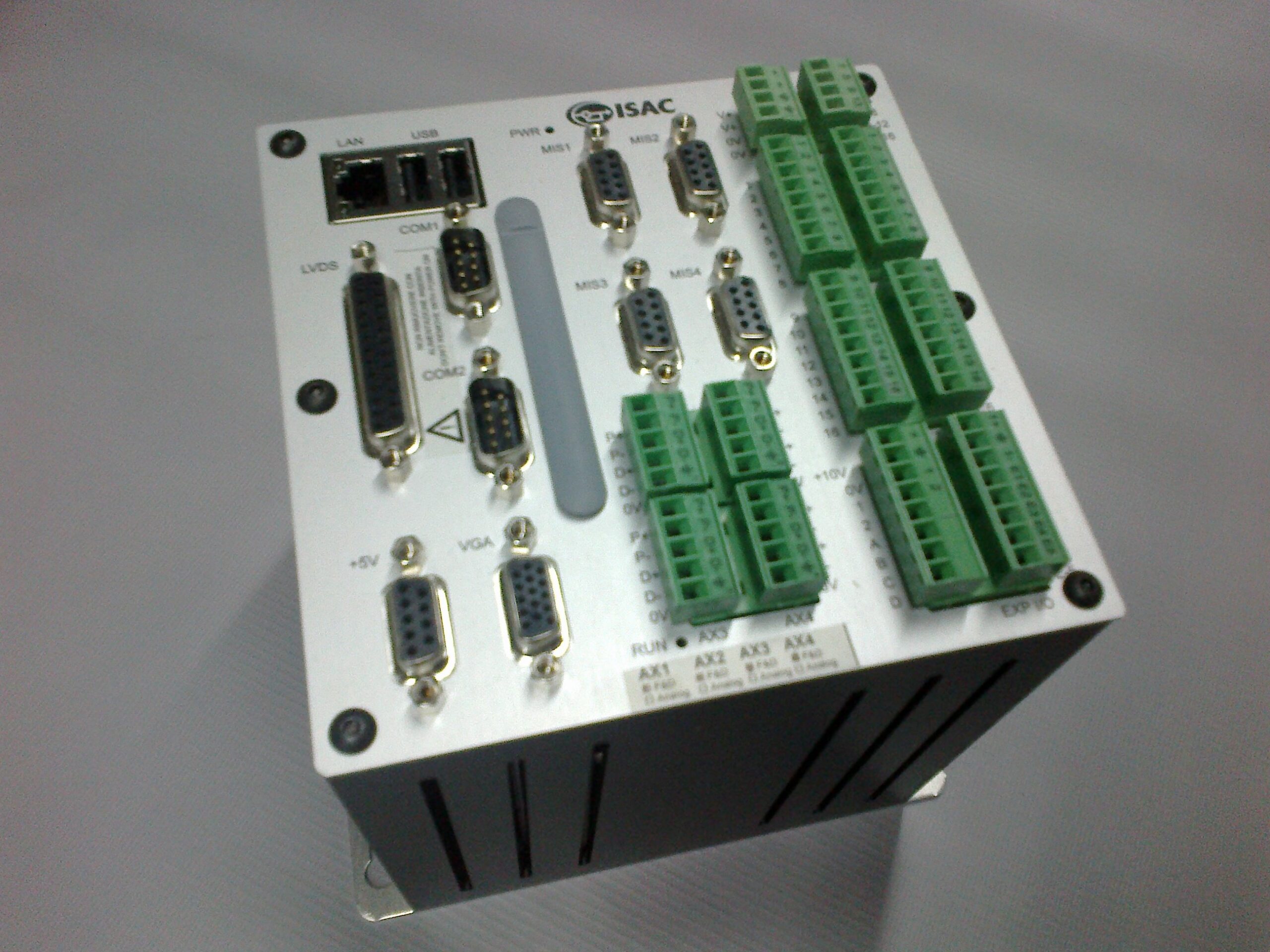

Umlawuli we-CNC

Eli candelo liphambili liguqulela isicwangciso se-CNC kwaye liphatha uthotho lwezinto ngokulandelelana, xa kufundwa inkqubo, umhloli wenza ukuba umsebenzi ohambelana nomatshini, uqhube intshukumo ye-axis kwaye ulandela ngokubanzi imiyalelo enikezwe kwinkqubo.

Kukho ezinye izinto ezisetyenziswayo:

- Ukuba kufunyenwe impazamo, lungisa (hlela) inkqubo.

- Yenza imisebenzi ekhethekileyo yokuqinisekisa (umzekelo, ukungasebenzi) ukuqinisekisa ukuchaneka kwenkqubo ye-CNC.

- Chaza igalelo elithile lomsebenzisi obalulekileyo, njengamaxabiso obude bezixhobo.

Inkqubo yeCAM

Kule nqaku, sichaza ukubaluleka kweeprojekthi (ukuXhaswa kweKhompyutha) xa kunzima ukubhala iinkqubo ze-CNC ngenxa yokungabikho kolwazi lomqhubi okanye izicelo ezinzima, kwiimeko ezininzi iinkqubo zeCAM zingasetyenziselwa ngokubambisana neComputer Aided Design (CAD) .

Umqhubi ubonisa kuphela isenzo sokuchithwa esiza kwenziwa, kwaye isicwangciso sivelisa ngokuzenzekelayo inkqubo. Oku kususa imfuno yokuchaza kwakhona ukuhanjiswa kwesiqwengana somsebenzi kwisicwangciso.

Inkqubo ye-DNC

Xa iprojekthi iqhubekile (ngesandla okanye ngenkqubo), kufuneka iqhutywe kumlawuli kwaye kule nkqubo yokuhanjiswa kwamanani (DNC) isetyenziswa.

Le nkqubo yikhompyuter eqhagamshelwe ngomatshini omnye okanye nangaphezulu ye-CNC, ngokwesiko, ukuhanjiswa kweenkqubo kuqhutywa kusetyenziswa umgaqo-nkqubo osisiseko wonxibelelwano (RS-232C). Nangona kunjalo, isayensi iqhubele phambili ukubonelela abalawuli banamhlanje ngezakhono zonxibelelwano ezinkulu ukuze bakwazi ukunxibelelana ngeendlela zesiko (umzekelo, nge-Ethernet).

Amathuba omsebenzi anikezelwa yitekhnoloji ye-CNC

Ngokukhula kwaba matshini, intlupheko enkulu yabasebenzi abaqeqeshiweyo ukubasebenzisa iyamangalisa, ngapha koko, yintsimi ethembisayo apho umvuzo uphezulu kwaye nomsebenzi ophumeleleyo unokukhuliswa. Oku kulandelayo yimisebenzi ebangela umdla kuye nakubani na okhangela amathuba kwicandelo lezixhobo zomatshini ze-CNC.

Izinto eziluncedo ze-CNC

Kukho izibonelelo zokonyusa imveliso kunye nokunciphisa ixesha lokuvelisa, oomatshini kunye nezixhobo zikwabonelela ngeendlela ezahlukeneyo zombutho wakho, ezinje:

- Ukusebenza okuphezulu kunye neendleko eziphantsi.

- Ukuchaneka okukhulu kunye nomgangatho wemveliso ongcono.

- Ukuphucula inqanaba lokhuseleko lwabasebenzisi.

- Ngaba ubhetyebhetye ngokwaneleyo ekuphatheni iimveliso ezisisiseko kunye / okanye ezintsonkothileyo.

- Umqhubi omnye unokusebenzisa oomatshini abaninzi ngaxeshanye.

- Ukunciphisa ixesha lokujikeleza.

- Iilwimi ezininzi zenkqubo.

- Lawula kwaye ubeke emgangathweni iimveliso zakho.

- Ukusebenza ngokuchanekileyo okukhulu.

Nini ukusebenzisa CNC

Malunga nini nokusebenzisa iMHCN? Isigqibo sihlala sisombulula ngokusekwe kwimveliso kunye nohlalutyo lwenzuzo; Nangona kunjalo, kumazwe ethu angaphuhlisanga kuhlala kukho inertia factor ethintela oosomashishini ekubeni bathathe inyathelo lobuchwephesha, kangangokuba abantu bayakhuthazeka ukuba basebenzise obu buchwephesha, ezemali kunye nezinye iindlela zemveliso ziya kunceda ukuphucula ukubonakala kwenzuzo kolu hlobo lotyalo-mali.

Kwelinye icala, nje ukuba kule nkqubo, inkampani iya kugqithisa iteknoloji ngokukhawuleza, iphucule inqanaba lobuchwephesha. I-Phenomenon enje ayiqhelekanga, zenzekile amaxesha amaninzi kwinqanaba labathengi kwilizwe lethu, ngakumbi ePanama.

Kubalulekile ukukhankanya ukuba inkqubela phambili kwezobuchwephesha zikhokelele ubuntu ekubeni ngabathengi abakhulu beetekhnoloji, yiyo loo nto sisebenzisa izinto ezinje nge: Hi-Fi, iimoto, izixhobo zonxibelelwano kunye neekhompyuter. Ke kutheni ungathandabuzi? Kwaye sicinga ukuba asikwazi ukulungelelanisa itekhnoloji entsha yemveliso kumava ethu eshishini.

Ngoku makhe sijonge indlela yokusebenzisa okanye ukungasebenzisi i-CNC ngokobungakanani bemveliso:

- Xa usebenze kakuhle.

- Ukuveliswa rhoqo kwenqaku elifanayo elingaphakamanga kakhulu.

- Xa ubunzima beli nqaku abuphezulu kakhulu.

- Ngokutshintsha into okanye ukubonelela ngeemodeli ezininzi.

Izinto ngokubanzi

Okwangoku, kukho imeko-bume egcwele ulindelo kunye nokungaqiniseki, oku kungenxa yenxalenye enkulu yotshintsho olukhawulezileyo kwitekhnoloji yangoku, kuba ezi azikuvumeli ukuba zingene ngokupheleleyo, zenze kube nzima. Yenza okusemandleni akho, ii-odolo zikwatshintsha ngokukhawuleza kwezoqoqosho nakwezopolitiko, kuluntu olufana nolwethu (Amazwe aPhuhlayo) ukuthintela ukuvela kwezisombululo zalapha ekhaya okanye ezobunini kwezona ngxaki zethu zibalulekileyo.

Kuzo zonke ezi nguqu, enye yezona zinto zinempembelelo ngokungathandabuzekiyo iqulunqa umgaqo-nkqubo wehlabathi omtsha wentengiso evulekileyo, kunye nehlabathi. Konke oku kuthetha ngokhuphiswano olukhululekileyo, ke kubalulekile ukuba sisebenzise ishishini lethu ukuze likwazi ukuhlangabezana nemiceli mngeni kunyaka olandelayo.

Elinye eli candelo lishishini, lazisa izinto ezizisebenzelayo, nangona kunjalo kufuneka lenziwe ngeyona ndlela ifanelekileyo ukuze ikwazi ukufunxwa. Ngokuthe ngcembe yamkela ubuchwepheshe obutsha ngexesha elifanelekileyo; konke oku akuyi kulityalwa, imbuyekezo yembuyekezo kunye namandla emveliso.

Enye yezinto ezibalulekileyo zokuzalwa ngokutsha koomatshini, ngumatshini wolawulo lwamanani wekhompyuter, ibonelela ngezinye izinto eziluncedo ekufuneka zithathelwe ingqalelo ngononophelo, yile njongo yeli nqaku.

Mfundi othandekayo, silandele: Iindidi zezikena zeekhompyuter.