Yazi kuyo yonke le ndatshana yonke imininingwane mayelana ne- ukulawula izinombolo, incazelo ebalulekile yezinhlelo zayo kanye nezinhlelo zokusebenza abangayinika zona, kulesi sihloko uzokwazi ngendlela ethize nelula yonke inqubo ehilelekile.

Ukulawulwa Kwezinombolo

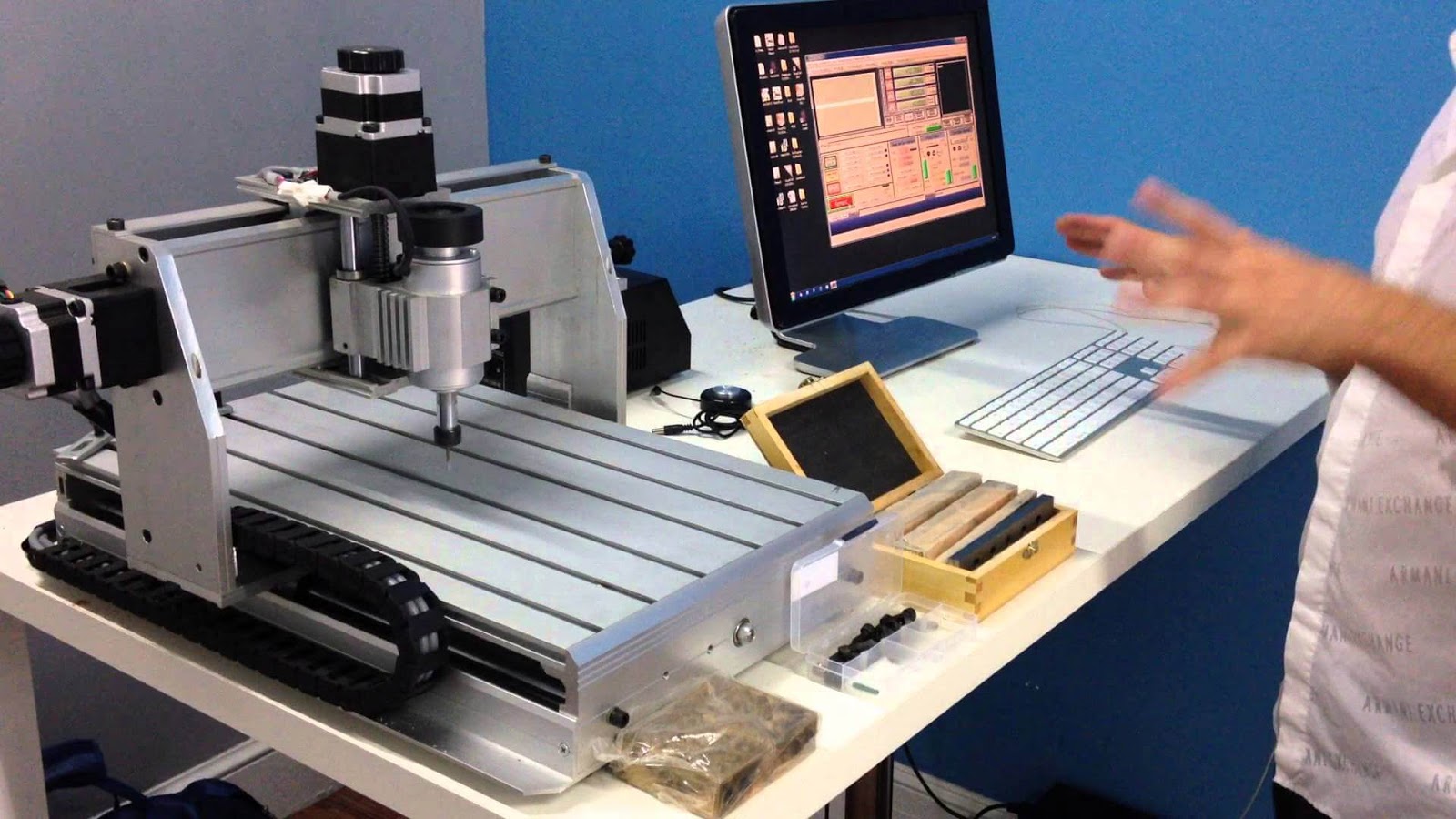

Kuyindlela ezenzakalelayo yemishini ephethwe ngokuhlela imiyalo endaweni yokugcina.

Umshini wokuqala werimothi wedijithali wakhiqizwa ngunjiniyela uJohn T. Parsons ngawo-1940 nango-1950. Wawususelwa kwimishini ekhona enezinjini eziguquliwe, inani lalo elihlobene ngesandla nemiyalo enikezwe kusibonakhulu se-punch card.

Lezi zindlela zokuqala ze-servo zakhula ngokushesha ngosizo lwe-analog nemishini yedijithali. Ukushibilika nokusetshenziswa kancane kwama-processor kusetshenziswe kabanzi ubuchwepheshe be-elekthronikhi kuzo zonke izinhlobo zamathuluzi, okuholele egameni le-digital decimal control, ikhompyutha digital control, ukuwaqhathanisa nemishini ebingenawo amakhompyutha.

Le ndlela iguqule imboni ngakho uma lolu hlobo lwesisho lusetshenziselwa ukubhekisa kulolu hlobo lwendaba amakhompyutha angenalo, ngakho-ke ngenxa yama-microprocessor ashibhile nohlelo olwenziwe lula lomshini.

Izimiso zokusebenza

Inqubo isuselwa ekuqapheleni ukuhamba komshini maqondana nenduku yezixhumanisi zensiza ngohlelo lwekhompyutha olwenziwa yikhompyutha. Okwe-lathe, ukufuduswa kwe-artifact kufanele kulawulwe kuma-axes amabili wokuxhumanisa: i-axis ye-X isetshenziselwa ukufuduka kwe-longitudinal yenqola kanye ne-axis ye-Z isetshenziselwa ukufuduswa komugqa kombhoshongo.

Kumshini wokugaya, ukufuduka okumi mpo okuhambelana ne-Y axis nakho kuyalawulwa.Ngalesi sizathu, zombili izindlela zokuhambisa i-lathe kanye ne-turret zifakiwe ama-servo motors, futhi esimweni se-lathe ngumshini wethebula lethebulethi, umshini wokugaya kuya ngamakhono omshini, awunakukhawulelwa kuzimbazo ezintathu.

Aplicaciones

Ingasetshenziselwa ukumodela insimbi, ukujoyina, ukubaza, amapulasitiki, amasekhethi aphrintiwe ngogesi, phakathi kwabanye. Ukusetshenziswa kohlelo lwe-CNC emshinini kuyithuluzi elandisa ukusebenza futhi ngasikhathi sinye livumela ukwakha imisebenzi okunzima ukuyigcwalisa ngamathuluzi wemishini ejwayelekile, njengokufezekisa indawo eyindilinga ngenkathi kugcinwa izinga eliphakeme lokunemba kobukhulu.

Ekugcineni, ukusetshenziswa kwe ukulawula izinombolo ngekhompyutha Inomthelela omuhle ezindlekweni zokukhiqiza ngokunciphisa izindleko zokukhiqiza zemishini eminingi nokwenza ngcono ikhwalithi.

Ukusetshenziswa kwe-CNC kunokushaqeka okuzuzisayo ezindlekweni zokukhiqiza ngokunciphisa izindleko zokwakha zemishini eminingi, ukugcina noma ukuthuthukisa ikhwalithi yazo.

Ukuhlela kusilawuli sezinombolo

Lolu hlobo lwezinhlelo lusebenzisa izindlela ezimbili:

Izinhlelo ezenziwe ngesandla

Kule phrojekthi, ingxenye ibhalwe ngokukhethekile ngokucabanga kanye nokubala okwenziwa kuphela ngumhlinzeki, iphrojekthi yemishini ifaka yonke idatha edingekayo ekusetshenzisweni kwengxenye leyo.

Njengoba umkhiqizi ngamunye esebenzisa uhlelo lwakhe lwe-NC, ukuqala kohlelo lwe-NC kubonakala ngokuthuthuka kwekhodi yohlelo. Ngemuva kwalokho, inqobo nje uma izinhlobo zezinhlelo ziyefana, isidingo sokumisa ikhodi yohlelo yisimo esisemqoka sohlelo olufanayo oluzosetshenziswa kumishini ehlukile.

Izinhlelo ezizenzakalelayo

Uma sikhuluma ngohlelo sikhuluma ngalokho okwenziwa yikhompyutha lapho idatha inikezwa yilowo owenza uhlelo lwengxenye, ivela ngolimi lokushintshana olubizwa nge-APT, oluzobe seluhunyushelwa olimini olufanele olimini ngalunye nge-post-processor, ulimi lomshini.

ngokunemba

I-eksisi yale mishini ivame ukuqhutshwa yisitepper esihlukanisa i-360 degree rotation ibe yizinyathelo ezingama-200 zalezi zinyathelo. Ngakho-ke, ukunemba kwe-eksisi kuzonikezwa yi-pitch ye-eksisi enkulu ehambayo. Kulokhu, inani lezinyathelo liyi-200, indawo ejikelezayo yethuluzi, isibonelo: uma i-X-axis spindle ene-pitch ye-1mm ihlukaniswe ngezinyathelo ezingama-200 zemoto, ithuluzi lomshini linganikeza ukunemba kwe-0,005 mm kule eksisi.

Ngaphambi nangemva kokulawulwa kwamanani (CNC)

Kusukela ekuqaleni kwekhulu lama-60, ukwanda kwezimboni okuqhumayo nokusetshenziswa okukhulu kwemishini yezimoto kudinge ukufunwa njalo kwezinqubo ezisebenza kangcono. Kuze kube yiminyaka engama-65-XNUMX edlule, umsebenzi onzima odingekayo emisebenzini yezimboni awudingi nje kuphela iqembu elikhulu labasebenzi, kepha uphinde wathinta ikhwalithi, ukunemba nokuphindeka, izindleko ezikhuphukile, kanye nokwehliswa komkhiqizo.

Singayibona ngezinga elingakanani ngesibonelo esilula. Isibonelo, abantu abaningi abasebenza esitolo semishini bajwayelene nomunye wemisebenzi elula yokwenza izinto, baze babhoboze nezimbobo zensimbi eshisiwe ngomshini wokubhoboza ngesandla.

Ukuze wenze lokhu, u-opharetha kufanele enze imisebenzi eminingi: beka ipuleti phansi, ubeke kancane ku-chuck bese uyilungisa othini lokuphotha, khetha isivinini ngokushintsha isondo lokugijimisa indiphi elenzelwe into esindayo, sebenzisa i-spindle bese usebenzisa i-lever noma i-roller roller iphepha liqondisa imbobo ephepheni elizocutshungulwa.

Manje cabanga ukuthi kungenzeka yini ukwenza inqubo enjalo endaweni yezimboni, lapho kufanele kwenziwe khona amakhulu emigodi ngamakhulu amaphepha ngesikhathi esifushane kakhulu ngezindleko eziphansi kakhulu kanye nekhwalithi ephezulu yokukhiqiza.

Yile ndlela owethulwa ngayo umqondo wokulawulwa kwezinombolo (NC) kumishini yokugaya yaseMelika ngawo-1950. Imishini yokugaya yayisebenzisa i-vacuum valve kanye ne-punch card technology ukulayisha imininingwane.

Ngasekuqaleni kweminyaka yama-1960, amashubhu okugcoba athathelwa indawo ama-transistor, kwaze kwaba yilapho kufika amakhompyutha ngawo-1970 kusungula isisekelo esicacile salokho manje esikubiza ngobuchwepheshe bokubhala. ukulawula izinombolo ngekhompyutha (CNC).

Lawa machipisi enze inguquko kuwo wonke umkhakha wokulawulwa kwezinombolo futhi aqaphele ukuhlanganiswa kwemisebenzi, njengomphelelisi wohlelo oluthuthukile, ukumelwa okucacile kwezindlela zamathuluzi, kanye nemijikelezo yenethiwekhi.

Lawa machips abe nokuxokozela okuphelele kulo mkhakha wokuqapha futhi aqaphele ukuhlanganiswa kwemisebenzi, njengezinsiza ezithuthukisiwe zohlelo, ukumelwa ngokuqhafazayo kwemikhondo yento, ama-subroutines nemijikelezo esemathinini, ukuxhumana namanethiwekhi.

Ngesikhathi sama-90s, ulwazi lwe ukulawula izinombolo ngekhompyutha.

Ekuqaleni kweminyaka yama-90, ulwazi lwe-CNC oluvulekile lwethulwa, oluyivumela ukuthi lwenziwe ngezifiso futhi luhlanganiswe nolwazi lomuntu, ukuhlelwa kokuqhafaza, ukuxhumana kwedijithali nedrayivu nezinye izinzuzo eziningi ezisinikeze izixazululo ezibalulekile zemishini yokuqapha.

Usebenza kanjani umshini we-CNC?

Lokhu ngokuyisisekelo kulawula umshini futhi kuthola ama-oda ngesimo samakhodi avela kumakhompyutha bese kuwuguqula ube amasiginali kagesi ngesoftware yawo ukuqala injini. Lapho sebeqale uhlelo lokudlulisa, izimbazo zemishini ye-CNC ziyadingeka ukukhiqiza ukunyakaza okudingwa inqubo yokukhiqiza.

Uma siqhubeka nokusebenzisa izivivinyo zezimboni njengesibonelo, la mazembe azobeka ithuluzi emgodini ozokwenziwa ngomshini (izimbazo ezimbili) bese wenza umsebenzi (i-eksisi lesithathu), izimbazo zibizwa ngamagama, amagama ajwayelekile kakhulu ezimbazo eziqondile yilezi I-X, Y ne-Z, ngenkathi amagama ajwayelekile kakhulu ama-rotary axes angama-A, B, no-C, izinhlelo ezimbili zingasetshenziselwa ukulawula ukunyakaza. Lezi zinhlelo zombili zingasebenza ngokuzimela noma ngokuhlangana zodwa:

Inani eliphelele, lapho izixhumanisi zephoyinti lendawo zibhekisa ekuqaleni kwalokhu, sebenzisa okuguquguqukayo X (inani elilinganisiwe lobubanzi bokugcina) no-Z (kulinganiswa ngokuqondiswa okuhambisana ne-axis yokujikeleza kwesikulufa).

Inani elandayo, lapho ukuxhumanisa kwemaki yendawo kubhekisele khona kumaka wamanje, sebenzisa u-U oguquguqukayo (ibanga eliyisisekelo) no-W (kulinganiswa ngokuqondiswa okuhambisana ne-eksisi yokuzungezisa i-eksisi enkulu).

Izesekeli ezihlelwe

Uma kunokulawulwa kokunyakaza kuphela, imishini ye-CNC ayizukusiza ngalutho, cishe yonke imishini ingahlelwa ngezinye izindlela, yingakho kufanele sinake ukuthi umshini uhlobene ngqo nezinsiza zawo ezihlelekile, ngakho-ke noma yimiphi imisebenzi edingekayo. zahlelwa Ithuluzi umshini CNC. Ngakho-ke, ngokwesibonelo, isikhungo semishini sizoba nemisebenzi okungenani elandelayo ehlelwe kahle:

Izikhungo zemishini ezinokushintsha okuzenzakalelayo kwethuluzi zingafaka amathuluzi amaningi ahlukahlukene ebhokisini eliphathekayo. Uma kunesidingo, okudingekayo kakhulu kungafakwa ngokushesha othini lokuphotha ukuze kulungiswe okuhambisanayo.

Ijubane lokuphotha nokwenza kusebenze: ungamane unikeze imininingwane ngejubane lokuphotha (ngo-rpm), uthi lokuphotha alukwazi ukugoqa ngokwewashi noma ngokuphikisana nokuhamba kwewashi kuphela, kepha futhi lume.

Isifriji: Lokhu kuyadingeka emisebenzini eminingi edinga isiqandisi sokuthambisa kanye nokupholisa idivayisi, ingasebenza futhi ingasebenzi ngesikhathi senqubo yokusebenza.

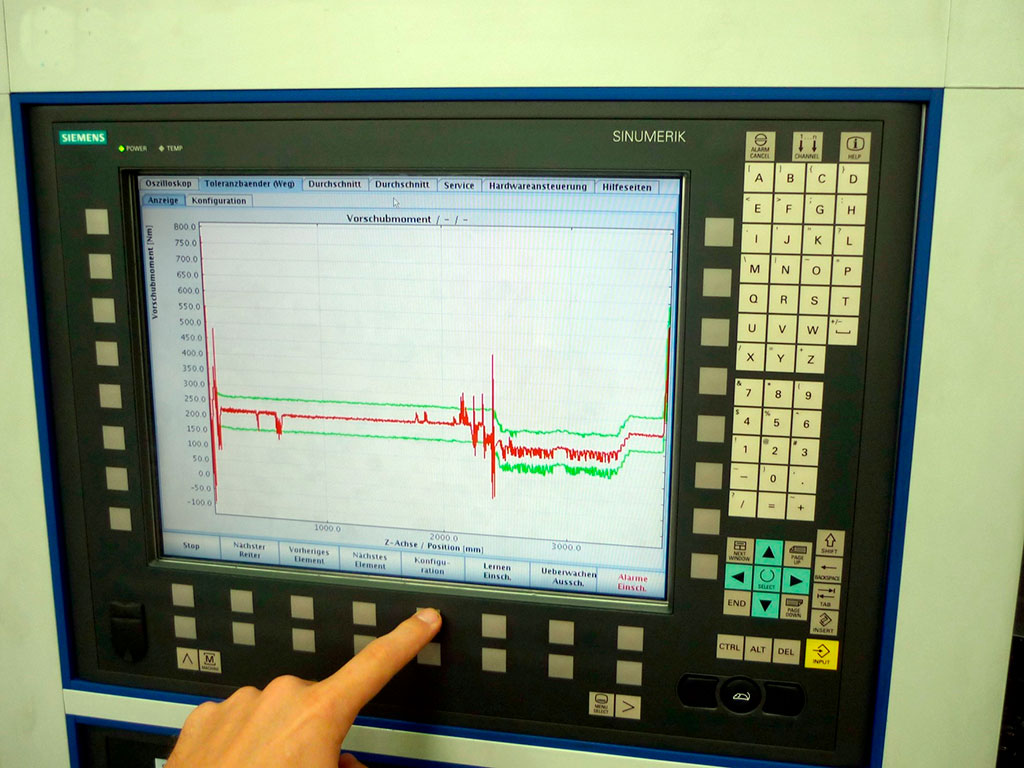

Uhlelo lwe-CNC

Lolu hlelo lususelwa kuhlu lokulandelana lapho lunemiyalo okufanele ilusebenzise, lezi zinkomba zibizwa ngokuthi izinhlelo ze-cnc, okumele ziqukathe lonke ulwazi oluyimpoqo ukwenza ingxenye leyo.

Izinhlelo ze-CNC zibhalwe ngezilimi ezisezingeni eliphansi ezibizwa nge-G no-M, zenziwe zaqiniswa yi-ISO 6983 (International Organisation for Standardization) ne-EIA (Electronic Industries Alliance) RS 274, futhi yakhiwe ngemiyalo ejwayelekile (G code) nezinye (Ikhodi M).

Uhlelo luhlinzeka ngesakhiwo semisho esakhiwe ngamabhulokhi, kuqala ngohlamvu N, njengoba kukhonjisiwe kumfanekiso olandelayo, lapho isenzo ngasinye noma isenzo senziwa ngokulandelana, ibhulokhi ngalinye libaliwe futhi ngokuvamile liqukethe umyalo.

Kunamakhodi acacisa ukusebenza kokuhamba kwezinto ezisetshenziswayo okukhulunywa ngazo (ngokwesibonelo, ukushesha okusheshayo, ukusondela kusengaphambili, ikhefu, umjikelezo), ngenkathi amanye amakhodi echaza eminye imisebenzi edingekayo yezingxenye zemishini, kepha ayihambelani nokuhamba kwensimbi ( isibonelo, ukuqala kokuphotha KANYE nokuma, ukuguqulwa kwamathuluzi, ukupholisa, ukumisa uhlelo).

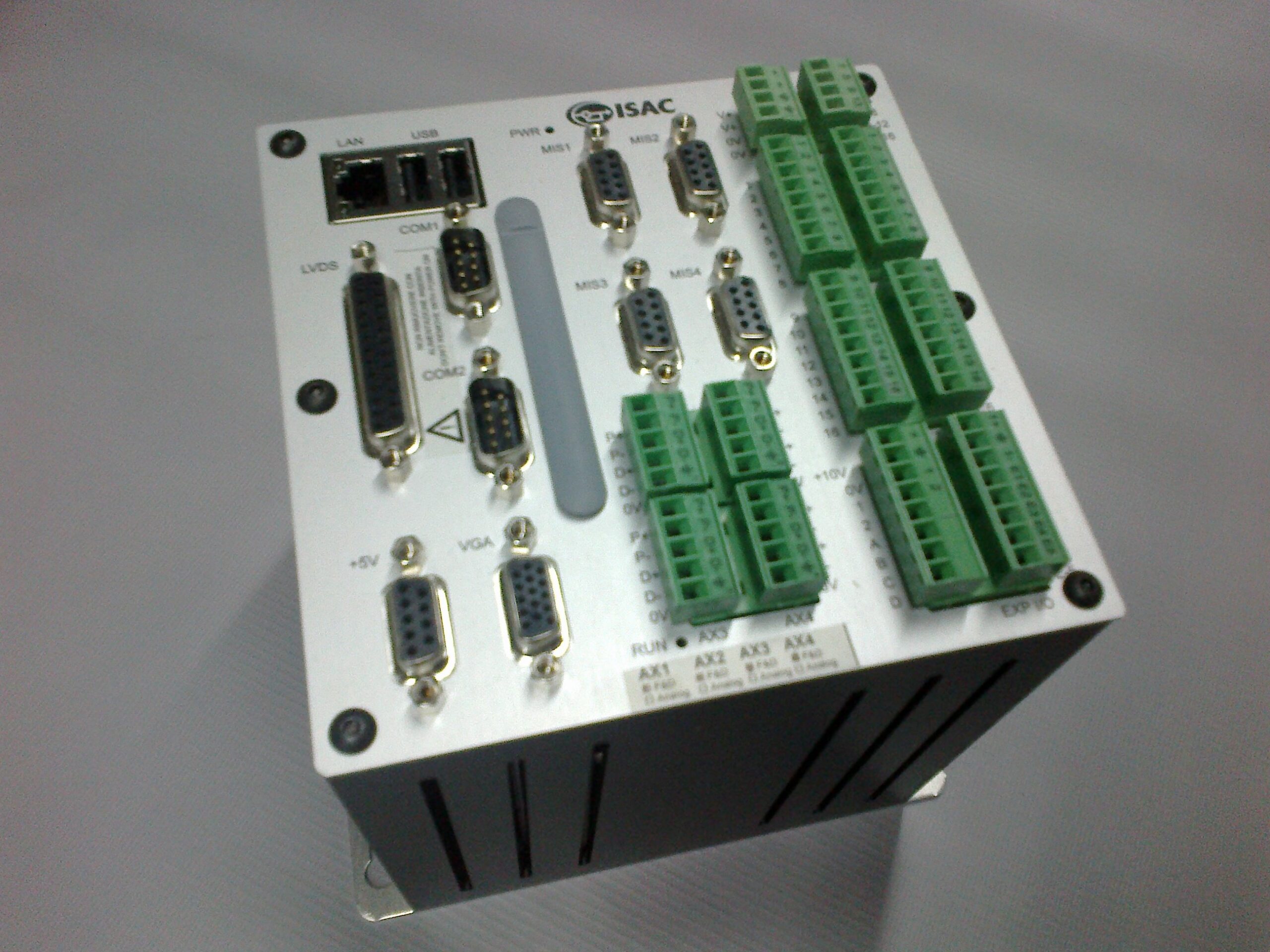

Isilawuli se-CNC

Le ngxenye eyisihluthulelo ihumusha uhlelo lwe-CNC futhi iphatha uchungechunge lwezinto ngokulandelana, lapho ifunda uhlelo, umhloli wenza kusebenze ukusebenza komshini ohambisanayo, aqhube ukunyakaza kwe-eksisi futhi ngokuvamile alandele imiyalo enikezwe ohlelweni.

Kukhona okunye ukusetshenziswa okuyi:

- Uma kutholakala iphutha, shintsha (hlela) uhlelo.

- Yenza imisebenzi yokuqinisekisa ekhethekile (isibonelo, idle) ukuqinisekisa ukunemba kohlelo lwe-CNC.

- Cacisa okokufaka okubalulekile kwe-opharetha, okufana namanani wobude bethuluzi.

Uhlelo lweCAM

Kule ndatshana, sikhuluma ngokubaluleka kwamaphrojekthi (i-Computer Aided Manufacturing) lapho kunzima ukubhala izinhlelo ze-CNC ngenxa yokushoda kolwazi lwe-opharetha noma izinhlelo eziyinkimbinkimbi, ezimweni eziningi izinhlelo ze-CAM zingasetshenziswa ngokubambisana neComputer Aided Design (CAD) .

U-opharetha ukhombisa kuphela isenzo semishini okufanele senziwe, futhi uhlelo luzivezela lona uhlelo ngokuzenzekelayo. Lokhu kususa isidingo sokuchaza kabusha ukusatshalaliswa kwesiqephu somsebenzi sohlelo.

Uhlelo lwe-DNC

Lapho iphrojekthi ithuthukile (ngesandla noma ngohlelo), kufanele ithathwe kwisilawuli futhi kulokhu kusetshenziswa uhlelo lokusabalalisa izinombolo (DNC).

Lolu hlelo luyikhompyutha exhunywe kwinethiwekhi enomshini owodwa noma eminingi ye-CNC, ngokwesiko, ukudluliswa kwezinhlelo kwenziwa ngokusebenzisa umthetho olandelanayo wokuxhumana olandelanayo (RS-232C). Kodwa-ke, isayensi iqhubekile nokuhlinzeka abalawuli banamuhla ngamakhono amakhulu wokuxhumana ukuze bakwazi ukuxhumana ngezindlela zendabuko (ngokwesibonelo, nge-Ethernet).

Amathuba omsebenzi ahlinzekwa ubuchwepheshe be-CNC

Ngokukhula kwale mishini, ububha obukhulu babasebenzi abaqeqeshiwe bokuyisebenzisa kuyamangaza, ngaleyo ndlela, kuyinsimu ethembisayo lapho umholo uphakeme impela futhi nomsebenzi ophumelelayo ungathuthukiswa. Okulandelayo yimisebenzi ejabulisa kakhulu kunoma ngubani ofuna amathuba emkhakheni wamathuluzi womshini we-CNC.

Izinzuzo ze-CNC

Kunezinzuzo zokwanda komkhiqizo nokunciphisa isikhathi sokukhiqiza, imishini namathuluzi nakho kunikeza izinzuzo ezahlukahlukene zenhlangano yakho, njenge:

- Ukusebenza okuphezulu nezindleko eziphansi.

- Ngokunemba Greater kanye nekhwalithi yomkhiqizo ongcono.

- Thuthukisa izinga lokuphepha kwabasebenza opharetha.

- Yiba nokuvumelana nezimo okwanele ukuphatha imikhiqizo eyisisekelo kanye / noma eyinkimbinkimbi.

- Opharetha oyedwa angasebenzisa imishini eminingi ngasikhathi sinye.

- Yehlisa isikhathi somjikelezo wokusebenza.

- Izilimi eziningi zokuhlela.

- Lawula futhi ulinganise imikhiqizo yakho.

- Ukunemba kokusebenza okukhulu.

Uyisebenzisa nini i-CNC

Mayelana nokuthi uyisebenzisa nini i-MHCN? Isinqumo sivame ukuxazululwa ngokuya ngokuhlaziywa kokukhiqiza nenzuzo; Kodwa-ke, emazweni ethu angathuthuki kahle kuvame ukuthi kube ne-inertia factor evimbela osomabhizinisi ekuthatheni i-elekthronikhi kwezobuchwepheshe, kangangoba abantu banogqozi lokusebenzisa lobu buchwepheshe, izindlela zezimali nezokukhiqiza ezizosiza ekwenzeni ngcono ukubonakala kwenzuzo yalolu hlobo lokutshala imali.

Ngakolunye uhlangothi, uma lokhu kule nqubo, inkampani izodlulisa ubuchwepheshe ngokushesha, ithuthukise izinga lobuchwepheshe. Izimo ezinjengalezi azivamile, zenzeke kaningi ezingeni labathengi ezweni lethu, ikakhulukazi ePanama.

Kubalulekile ukusho ukuthi ukuthuthuka kwezobuchwepheshe kuholele ekutheni isintu sibe ngabathengi abakhulu bezobuchwepheshe, yingakho sisebenzisa izinto ezithile ezifana nalezi: iHi-Fi, izimoto, okokuxhumana namakhompyutha. Manje kungani ungabaza? Futhi sicabanga ukuthi asikwazi ukuvumelanisa ubuchwepheshe obusha bokukhiqiza buhambisane nesipiliyoni sebhizinisi lethu.

Manje ake sibheke ukuthi ungayisebenzisa kanjani noma cha i-CNC ngokwenani lokukhiqiza:

- Lapho usebenza kahle.

- Imvamisa yokukhiqiza yendatshana efanayo engekho phezulu kakhulu.

- Lapho ubunzima be-athikili bungaphakeme kakhulu.

- Ngokushintshanisa into noma ukuhlinzeka ngamamodeli amaningi.

Okuvamile

Njengamanje, kunemvelo egcwele okulindelwe nokungaqiniseki, lokhu kungenxa enkulu yezinguquko ezisheshayo kubuchwepheshe bamanje, ngoba lokhu akuvumeli ukuthi kungene ngokuphelele, kwenze kube nzima. Yenza okusemandleni akho, ama-oda nawo anezinguquko ezisheshayo kwezomnotho nezepolitiki, emphakathini ofana nowethu (Amazwe Asathuthuka) ukuvimbela ukuvela kwezixazululo zasendaweni noma eziphathelene nenkinga yethu ebaluleke kakhulu.

Kuzo zonke lezi zinguquko, enye yezinto ezinethonya elikhulu ngokungangabazeki isungula inqubomgomo yezwe entsha yemakethe evulekile, kanye nokuhwebelana kwembulunga yonke. Konke lokhu kukhuluma ngokuncintisana kwamahhala, ngakho-ke kuyadingeka ukuguqula imboni yethu ukuze ikwazi ukubhekana nezinselelo ngonyaka ozayo.

Enye indlela yalokhu imboni, eyethule izinto ezishintshayo, kepha-ke kufanele yenziwe ngendlela efanelekile ukuze ikwazi ukungena. Kancane kancane wamukele ubuchwepheshe obusha ngesikhathi esifanele; konke lokhu ngeke kulibaleke, izici zembuyiselo kumandla otshalo-mali nokukhiqiza.

Enye yezinto ezibalulekile zokuzalwa kabusha kwe-automation, umshini wokulawulwa kwamanani wekhompiyutha, unikeza ezinye izinzuzo ezibalulekile okufanele zicatshangelwe ngokucophelela, lokhu kuyinjongo yalesi sihloko.

Mfundi othandekayo, silandele ku: Izinhlobo zamaskena wekhompyutha.