Know throughout this article all the details about the numerical control, the important definition of its systems and the applications that they can give it, in this article you will know in a specific and simple way all the process that it entails.

Numerical Control

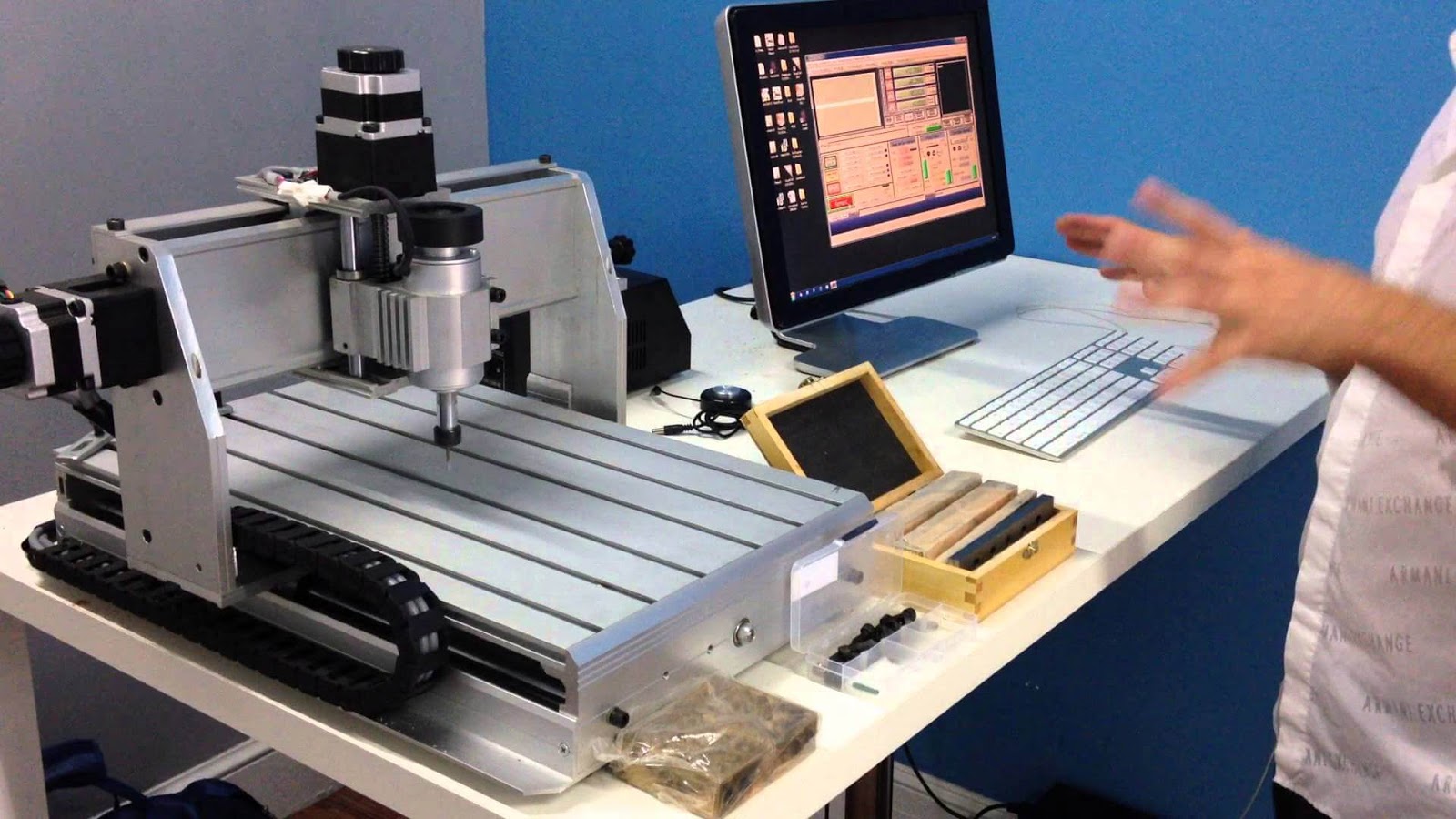

It is an automated method for machines that are managed by programming commands on a storage medium.

The first digital remote control machine was manufactured by engineer John T. Parsons in the 1940s and 1950s. It was based on existing machines with modified motors, the number of which was manually related to the instructions given on the punch card microscope.

These early servo mechanisms developed rapidly with the help of analog and digital equipment. The cheapness and miniaturization of processors have widely used digital electronic technology in all kinds of tools, resulting in the name of digital decimal control, computer digital control, to compare them to machines that did not have computers.

This method has revolutionized the industry so if this type of expression is used to refer to this type of subject that did not have computers, so thanks to the cheaper microprocessors and the simplified programming of the machine.

Principles of operation

The procedure is based on the monitoring of the movement of the machine in relation to the rod of coordinates of the apparatus by means of a computer program executed by a computer. For the lathe, the displacement of the artifact must be controlled on two coordinate axes: the X axis is used for the longitudinal displacement of the carriage and the Z axis is used for the lateral displacement of the tower.

For the milling machine, the vertical displacement corresponding to the Y axis is also controlled. For this reason, both the lathe and the turret displacement mechanism are installed servo motors, and in the case of the lathe it is a tabletop machine, the milling machine depends on of the machine's capabilities, it cannot be limited to three axes.

Applications

It can be used to model metal, joinery, carpentry, plastics, electronic printed circuits, among others. The application of the CNC system on the machine is a tool that increases performance and at the same time allows forming operations that are difficult to complete with conventional machine tools, such as achieving a spherical surface while maintaining a high degree of dimensional precision.

Finally, the use of computerized numeric control It has a beneficial impact on production costs by reducing the manufacturing costs of many machines and improving quality.

The use of CNC has a beneficial shock to production costs by mitigating the construction costs of many machines, maintaining or improving their quality.

Programming on the numerical control

This type of programming uses two methods:

Manual programming

In this project, the part is written exclusively by reasoning and calculations that only the operator does, the machining project incorporates all the data required for the machining of the part.

Since each manufacturer uses its own NC program, the start of the NC program is characterized by chaotic development of the programming code. Subsequently, as long as the types of programs are the same, the need to standardize the programming code is an indispensable condition for the same program to be used on different machines.

Automatic programming

When we talk about programming we are talking about what the computer does when the data is provided by the one who makes the programming of the part, it appears in an exchange language called APT, which will then be translated into the appropriate language for each language by the post-processor, language of machine.

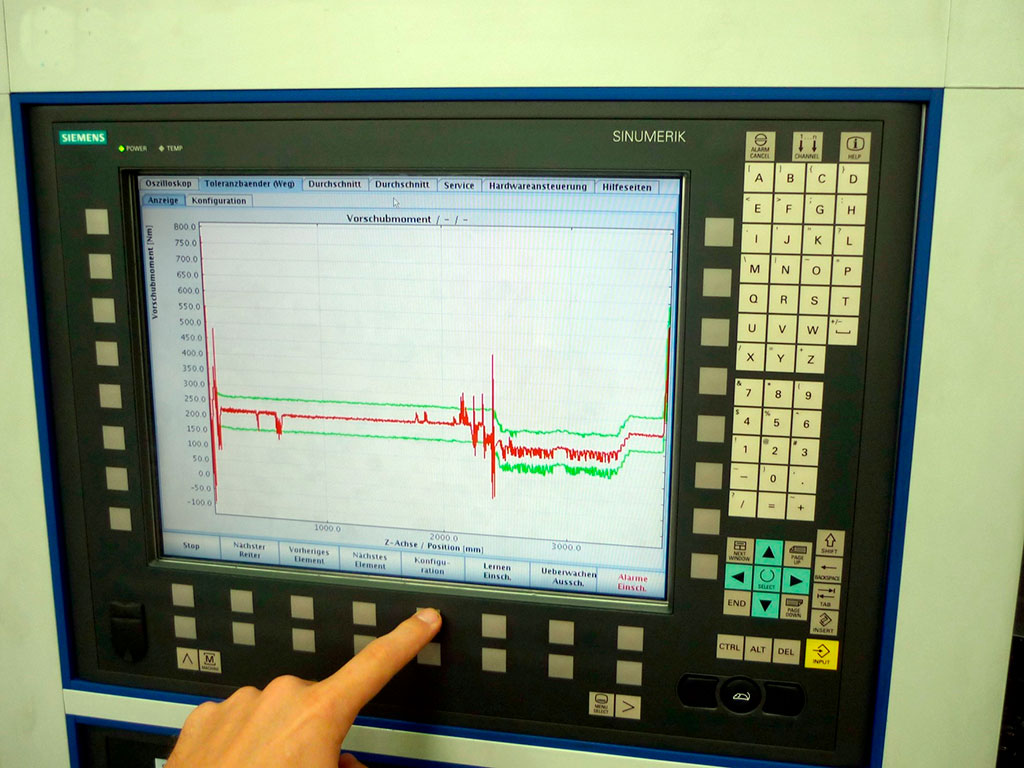

Precision

The axis of these machines is usually driven by a stepper motor that divides the 360 degree rotation into 200 steps of these steps. Therefore, the precision of the axis will be given by the pitch of the moving main axis. In this case, the number of steps is 200, the rotation position of the tool, example: if the X-axis spindle with a pitch of 1mm is divided into 200 steps of the motor, the machine tool can provide an accuracy of 0,005 mm on this axis.

Before and after numerical control (CNC)

Since the beginning of the 60th century, the explosive industrial expansion and the massive use of motorized machinery have required the constant search for more efficient processes. Until about 65-XNUMX years ago, the intensive labor required for industrial tasks not only required a large team of workers, but also affected quality, precision and repeatability, increased costs, and reduced production.

To what extent can we see it through a simple example. For example, many people who work in the machine shop are familiar with one of the simplest fabrication operations, even drilling holes in sheet metal with a hand drill.

To do this, the operator must perform multiple tasks: place the plate on the drilling floor, place the bit in the chuck and fix it on the spindle, select the speed by changing the pulley, activate the spindle and operate the lever or feed roller. paper guide the hole to the paper to be processed.

Now imagine the feasibility of running such a process in an industrial environment, where hundreds of holes must be made in hundreds of sheets of paper in the shortest time possible with the lowest cost and highest production quality.

This is how the concept of numerical control (NC) was introduced to American milling machines in the 1950s. The milling machines used vacuum valve and punch card technology to load data.

As early as the 1960s, vacuum tubes were replaced by transistors, until the advent of computers in the 1970s established a clear foundation for what we now call vacuum technology. numerical control by computer (CNC).

These chips have revolutionized the whole field of numerical control and have realized the integration of functions, as a complement to advanced programming, graphical representation of toolpaths, and network cycles.

These chips have had a total stir in this field of monitoring and have noticed the unification of functions, such as advanced programming aids, graphical representation of object paths, subroutines and canned cycles, communication and networks.

In the time of the 90s, the knowledge of the computerized numeric control, which allowed customizing it and making a combination with one's own knowledge, interactive graphic technique, and digital communication with the variator and many other very specific advantages of the machinery.

At the beginning of the 90s, open CNC knowledge was introduced, which allows it to be customized and combined with one's own knowledge, interactive graphic planning, digital communication with the drive and many other advantages that gave us significant solutions for the monitoring machinery.

How does a CNC machine work?

This basically controls the machine and receives orders in the form of codes from the computers and transforms it into electrical signals through its own software to start the engine. Once they start the transmission system, the axes of the CNC machines are necessary to generate the movements that the manufacturing process requires.

If we continue using industrial drills as an example, these axes will place the tool on the hole to be machined (two axes) and perform the operation (third axis), the axes are named with letters, the most common names for linear axes are X, Y and Z, while the most common names for rotary axes are A, B, and C, two systems can be used for motion control. The two systems can work independently or in combination with each other:

Absolute value, where the coordinates of the place point refer to the start of these, use the variables X (measured value of the final diameter) and Z (measured in a direction parallel to the axis of rotation of the screw).

Incremental value, where the location mark coordinates refer to the current mark, use the variable U (radial distance) and W (measured in a direction parallel to the axis of rotation of the main axis).

Programmable accessories

If there is only motion control, CNC machines will be useless, almost all machines can be programmed in other ways, that is why we must take into account that the machine is directly related to its appropriate programmable accessories, so any required functions It can be programmed on the CNC machine tool. Therefore, for example, a machining center will have at least the following specific programmable functions:

Machining centers with an automatic tool changer can accommodate many different tools in a portable box. If necessary, the most necessary can be quickly placed on the spindle for corresponding processing.

Spindle speed and activation: you can simply detail the spindle speed (in rpm), the spindle can not only roll clockwise or counterclockwise, but also stop.

Refrigerant: This is required for many operations that need refrigerant for lubrication and to cool the device, it can be activated and deactivated during the work process.

CNC program

This program is based on a sequence list where it has instructions to execute, these indications are called cnc programs, which must contain all the mandatory information to machine the part.

CNC programs are written in low-level languages called G and M, have been standardized by ISO 6983 (International Organization for Standardization) and EIA (Electronic Industries Alliance) RS 274, and are composed of general instructions (G code) and others ( Code M).

The program provides a sentence format made up of blocks, starting with the letter N, as shown in the following figure, where each action or action is executed sequentially, each block is numbered and generally contains a command.

There are codes that specify the movement functions of the apparatus in question (for example, rapid advance, radial advance, pause, cycle), while other codes describe other functions necessary for machining parts, but do not correspond to the movement of the apparatus (for example, spindle start AND stop, tool change, coolant, program stop).

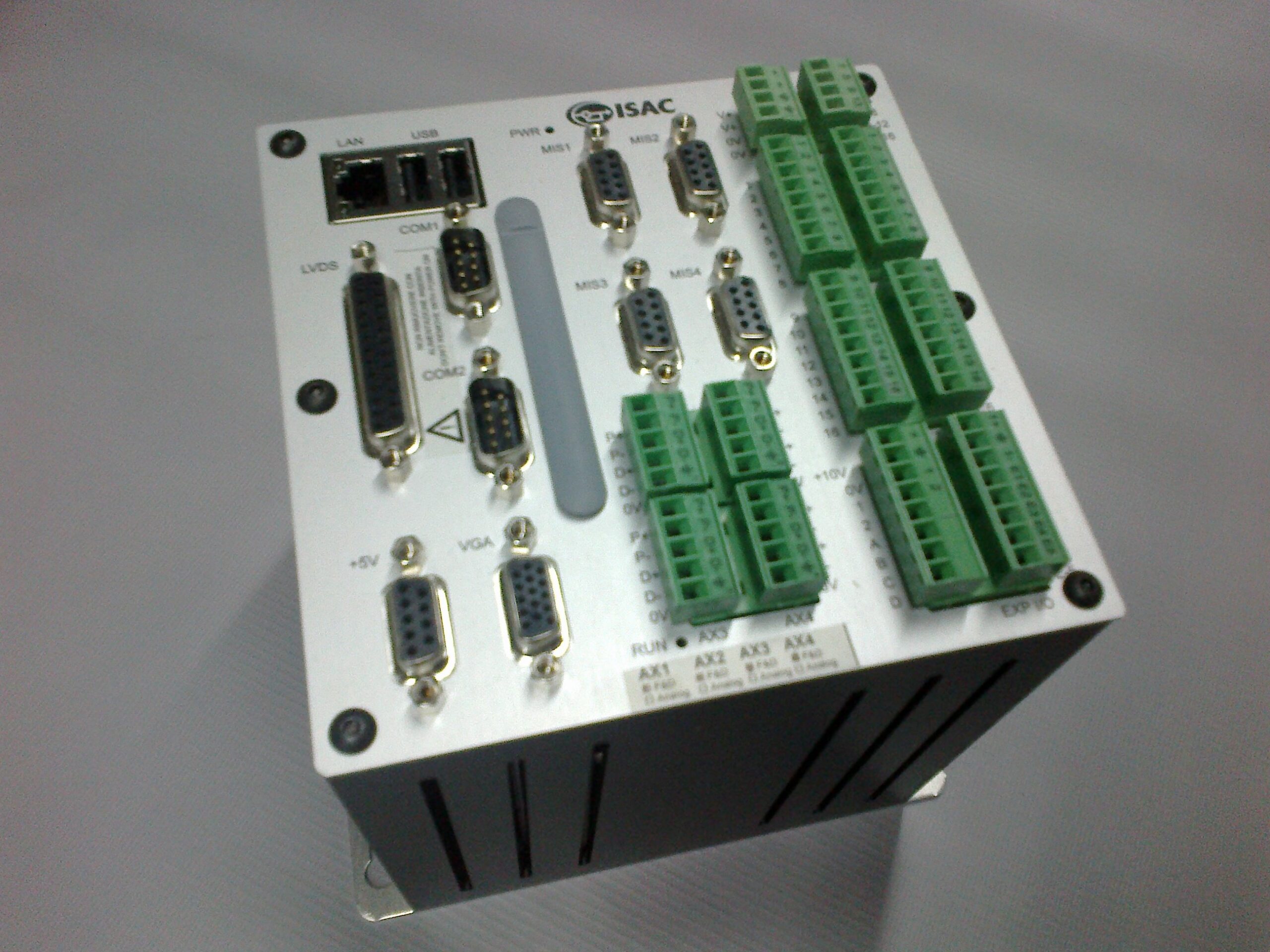

CNC controller

This key component interprets the CNC plan and handles a series of items in sequence, when reading the program, the inspector activates the corresponding machine function, drives the axis movement and generally follows the instructions given in the program.

There are other uses which are:

- If an error is detected, modify (edit) the program.

- Perform special verification functions (for example, idle) to confirm the accuracy of the CNC program.

- Specify certain important operator inputs, such as tool length values.

CAM program

In this article, we mention the importance of projects (Computer Aided Manufacturing) when it is difficult to write CNC programs due to lack of operator knowledge or complex applications, in many cases CAM programs can be used in conjunction with Computer Aided Design (CAD).

The operator only indicates the machining action to be executed, and the plan automatically produces the program. This removes the requirement to redefine the distribution of the work fragment for the plan.

DNC system

When the project is advanced (manually or by means of a program), it must be carried in the controller and for this a numerical control distribution system (DNC) is used.

This system is a computer that is connected in a network with one or more CNC machines, traditionally, the transmission of programs is carried out using the basic serial communication protocol (RS-232C). However, science has moved on to provide today's controllers with greater communication capabilities so that they can be networked in more traditional ways (for example, via Ethernet).

Job opportunities offered by CNC technology

With the growth of these machines, the serious poverty of trained personnel to run them is surprising, in such a way, it is a promising field in which the salary is quite high and a successful career can also be developed. The following are the most exciting jobs for anyone looking for opportunities in the field of CNC machine tools.

Advantages of CNC

There are advantages of increasing productivity and reducing time to produce, machines and tools also provide a variety of other advantages for your organization, such as:

- Higher performance and lower cost.

- Greater precision and better product quality.

- Improve the safety level of operators.

- Have ample flexibility to handle basic and / or complex products.

- One operator can operate multiple machines at the same time.

- Reduce operating cycle time.

- Multiple programming languages.

- Control and standardize your products.

- Greater operational precision.

When to use the CNC

About when to use MHCN? The decision is usually to resolve based on production and profitability analysis; However, in our underdeveloped countries there is usually an inertia factor preventing entrepreneurs from taking a technological leap, so much so that people are motivated to use these technologies, financial and production alternatives will help to improve the appearance of profitability of this type investment.

On the other hand, once this in this process, the company will transfer technology quickly, improve the technical level. Phenomenon like this is not uncommon, they have occurred many times at the consumer level in our country, especially in Panama.

It is important to mention that technological advances have led humanity to be large consumers of technology, which is why we use aspects of it such as: Hi-Fi, cars, communication equipment and computers. So why be skeptical? And we think that we are not able to adapt the new production technology to our business experience.

Now let's take a look at how to use or not CNC in terms of production quantity:

- When you have a high performance.

- Production frequency of the same article that is not very high.

- When the complexity of the article is not very high.

- By exchanging an item or providing multiple models.

Generalities

Currently, there is an environment full of expectations and uncertainties, this is due in large part to the rapid changes in current technology, because these do not allow it to be fully absorbed, making it difficult. Do your best, orders also have rapid economic and political changes, in a society like ours (Developing countries) to prevent the emergence of local or proprietary solutions to our most fundamental problem.

Of all these changes, one of the most influential is undoubtedly formulating a new world policy of open market, and globalization. All this speaks of free competition, so it is necessary to adapt our industry so that it can meet the challenges next year.

An alternative to this is the industry, introduced the elements of automation, however it must be done in the most appropriate way so that it can be absorbed. Gradually adopt new technologies at the right time; all this will not be forgotten, factors of return on investment and production capacity.

One of the important elements of the automation renaissance, is a computer numerical control machine, it provides other important advantages that must be carefully considered, this is the purpose of this article.

Dear reader, follow us on: Types of computer scanners.